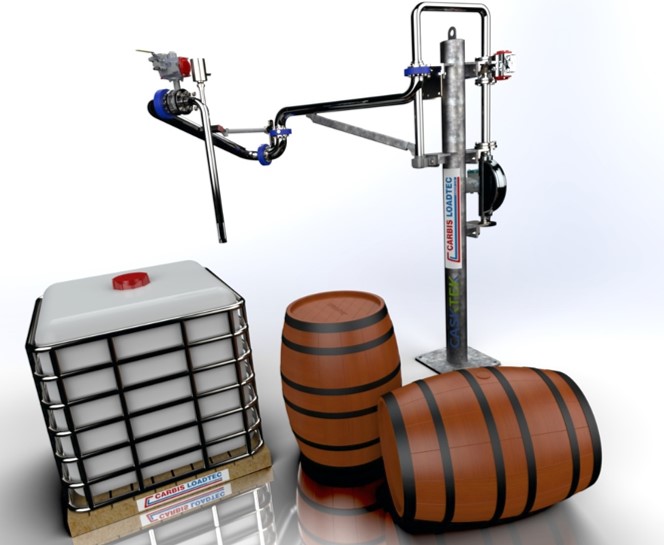

CaskTEK Filling System

What is it

A highly advanced cask filling system which uses the latest technology to fill casks quickly and accurately every time.

Combine the filling system with our CaskTEK software and fully control your cask filling, disgorging and reporting with the most advanced system on the market today.

FAST FILL TECHNOLOGY

American Standard Barrel filled in 40 seconds.

EASY OPERATOR HANDLING

Articulated arm allows easy movements.

HIGH ACCURACY FILLING

Guided wave radar housed in the filling head.

CONSISTENT PERFORMANCE

Bottom filling casks to reduce foaming and improve consistency.

LOW MAINTENANCE COSTS

High-quality robust installation with no braided hoses.

Designed by the Industry, For the Industry

The filling system was developed over 12 months in collaboration with Diageo, Siemens and the Advances Forming research Centre, specifically to address the need of inaccurate cask filling.

Extensive use of an advanced digital twin allowed for accelerated design and prototyping of the system together with advanced manufacturing.

Accurate & Consistent Filling

The innovative filling head has an integrated guided wave radar which provides real-time measurement of the fill level throughout the cycle. This allows a fast fill, every time to the same defined level within a cask.

The innovative filling head has an integrated guided wave radar which provides real-time measurement of the fill level throughout the cycle. This allows a fast fill, every time to the same defined level within a cask.

A longer lance design bottom fills the casks to reduce foaming and reduces fill turbulence which improves the accuracy of volume measurement.

Advanced design which uses modern technology to solve decades-old issues for whisky production.

Fast Fill Performance

An articulated arm from industry specialists Carbis-Loadtec allows operators the freedom of movement needed to quickly work in a production environment. Without the need for braided hoses, it reduces maintenance costs and downtime requirements.

An articulated arm from industry specialists Carbis-Loadtec allows operators the freedom of movement needed to quickly work in a production environment. Without the need for braided hoses, it reduces maintenance costs and downtime requirements.

Easy Handling & Reduced Maintenance

An articulated arm from industry specialists Carbis-Loadtec allows operators the freedom of movement needed to quickly work in a production environment. Without the need for braided hoses, it reduces maintenance costs and downtime requirements.

An articulated arm from industry specialists Carbis-Loadtec allows operators the freedom of movement needed to quickly work in a production environment. Without the need for braided hoses, it reduces maintenance costs and downtime requirements.

Demonstration Rig Available

We have a full demonstration facility available for customers to visit and practise filling casks and see the performance of the system. The facility is sited within the Light Manufacturing Centre (LMC), part of the new National Manufacturing Institute for Scotland in Renfrew, Glasgow. Contact us to book your demonstration.